WOODSAFE® SP FIRE 105

The two-facade systems from Woodsafe Timber Protection AB gives you the freedom to choose between a traditional painted facade or a natural aging facade. Through our partners, a fully documented wooden facade is offered where construction of the structure, ventilation, insulation, substrate and surface treatment are included in the approval. Both WOODSAFE® systems have type-approved properties according to utility class EN16755 EXT. Choosing WOODSAFE® means that the legal requirements according to the Housing Agency's building regulations and Plan, and the Building Act are complied with.

Tip from Woodsafe Timber Protection AB

When prescribing, procuring and installing a wooden facade, you need to take into account the fire requirements set for building class and business class. The fire requirements for apartment buildings or buildings with higher protection requirements often require SP FIRE 105.

But don't forget the utility class.

"Fire protection in an exterior environment without EN16755 EXT properties is not recommended, as it endangers both safety and financial values"

Type-approved wooden facade according to BBR, Plan and Building Act (PBL)

Which fire protection requirement you need to take into account is based on building class and business class. In apartment buildings over two floors, the building is classified as building class Br1 or higher depending on the activity class. In the current case, the wooden facade construction must be approved according to SP FIRE 105, which is a construction fire test, unlike Euroclass B which is used in our neighboring countries, for example B-s2,d0 (Denmark) and B-s3,d0 (Norway). Fire classification SP FIRE 105 can be a replacement for non-combustible facade based on the functional requirements for falling parts, heat radiation, eaves temperature and fire spread along the surface of the cladding and in the air gap.

WOODSAFE® PRO™ and WOODSAFE® Exterior WFX™ have been tested in several variations and several combinations with underlying substrate. Contact one of our partners for more information about what has been tested and approved.

Choosing facade cladding SP FIRE 105

SP FIRE 105 means a complete facade system can be made up of wooden facade, ventilation battens, insulation and a frame consisting of wood, concrete or steel. These widely different conditions affect the course of fire and it is therefore important to choose wooden facade systems with approved fire tests.

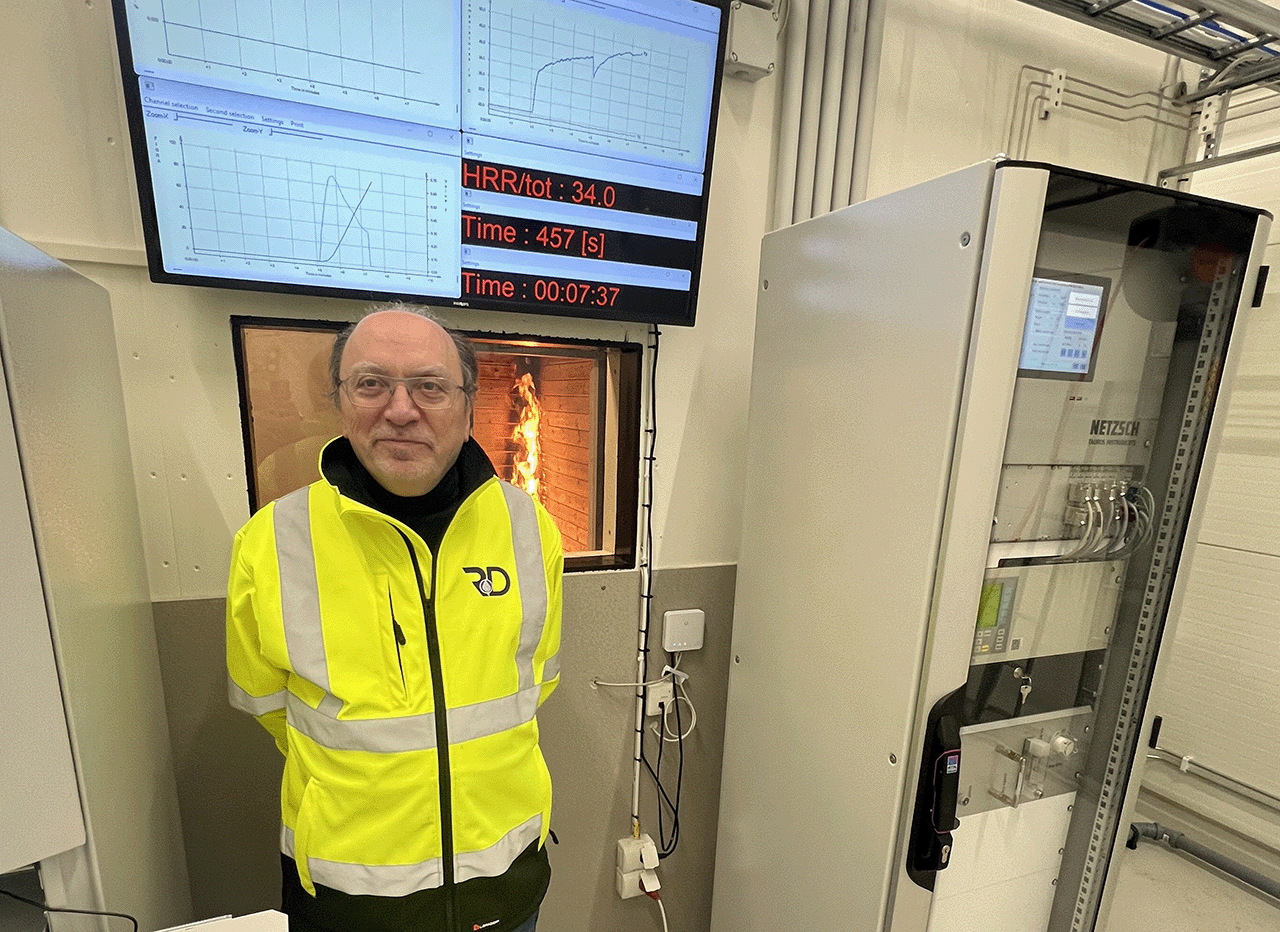

Essentially, the SP FIRE 105 test consists of determining radiant heat from the cladding (<80kW/m2), eaves temperature (<450°C), fire spread along the surface of the cladding and in the structure and falling parts. During testing, it is not unusual to have burn-through and therefore it is important that the insulation is included in the test, as insulation and air gap have a great influence on the process. Materials such as stone wool and glass wool are classified as A2, even though glass wool has completely different properties than stone wool when tested. Other insulation materials, for example phenol-based insulation boards, clearly affect the results and it is important to have them documented.

WOODSAFE® systems are fully tested in a variety of designs that are available through carefully selected partners. In the systems, there are verified results in combination of wood types, insulation materials such as Rockwool, Finnfoam, Isover, Kingspan, 3-layer board and KL-wood as a frame

Important in choosing a wooden facade with approved properties according to SP FIRE 105.

Don't forget the utility class! An approved SP FIRE 105 system without utility class EN16755 EXT is not a long-term sustainable investment.